machine fleet

15888

page-template,page-template-full_width,page-template-full_width-php,page,page-id-15888,bridge-core-2.7.5,qode-page-transition-enabled,ajax_fade,page_not_loaded,,qode-title-hidden,qode-theme-ver-26.0,qode-theme-bridge,qode_header_in_grid,wpb-js-composer js-comp-ver-6.6.0,vc_responsive

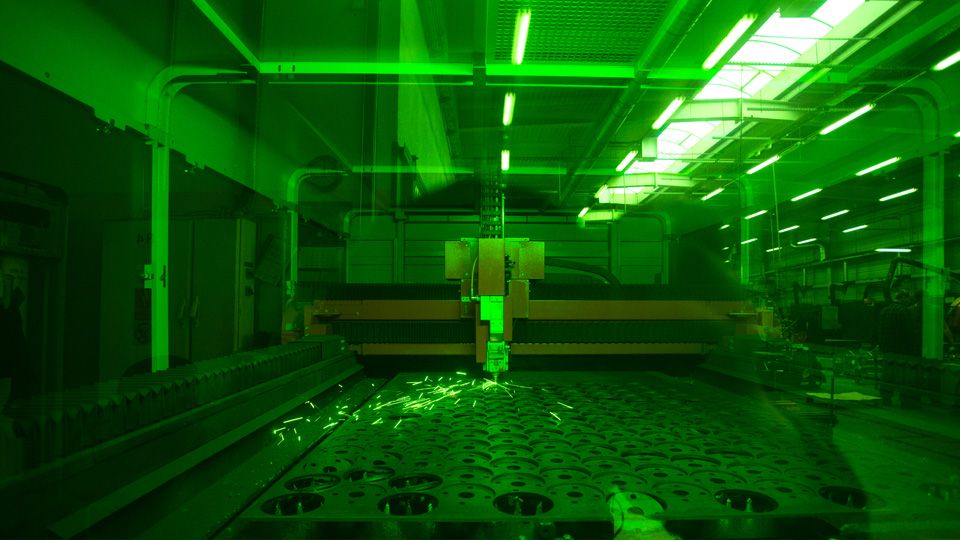

laser cutting of steel (worktable of 3000 x 1500 mm)

We have capabilities to cut:

- structural steel, up to 20 mm thick

- stainless/acid resistant steel, up to 12 mm thick

- aluminum, up to 10 mm thick

Laser cutting guarantees:

- high quality and precision of cut – 0.1mm

- 100% repeatability of cut elements

- smooth cut surface and edges

- ability to cut very small element

- cutting work pieces of very complex shapes

sheet metal bending on press brake with pressure of 120 t

We have the capability to bend sheet metal on press brake:

- maximum cut length – 3000 mm

- bent element thickness from 0.5 mm to 8 mm

The primary benefits of press brake bending are:

- 100% repeatability of bent shapes

- bending of complex shapes

- low unitary cost in case of larger series

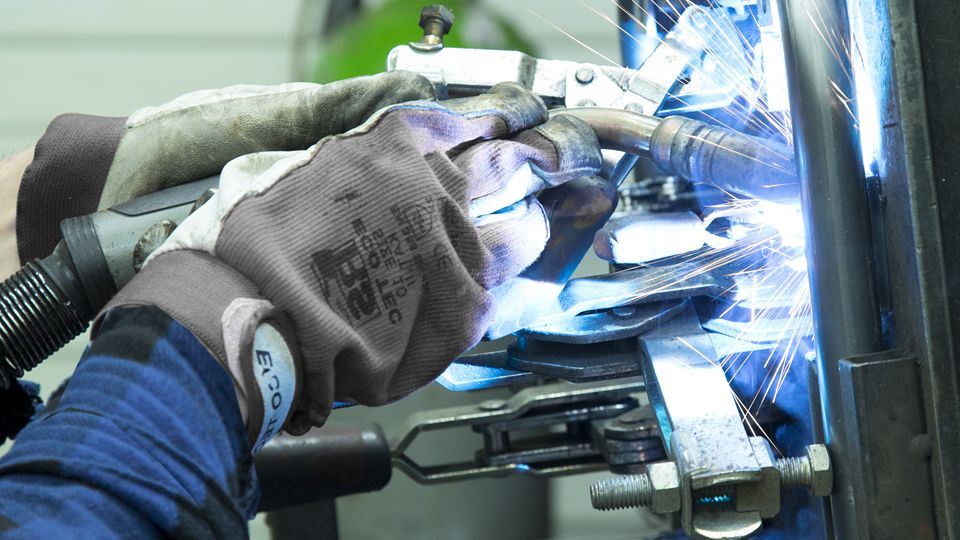

MIG/MAG welding

We weld with MAG/MIG method.

- It is welding with consumable wire electrode in presence of inert shielding gas (argon, helium) or active shielding gas (carbon dioxide with argon).

- In this method the electric arc forms between the welded material and the consumable electrode in the form of a wire.

Benefits:

- very high welding efficiency

- very good weld quality

- low cost

- capability to automate the procedure

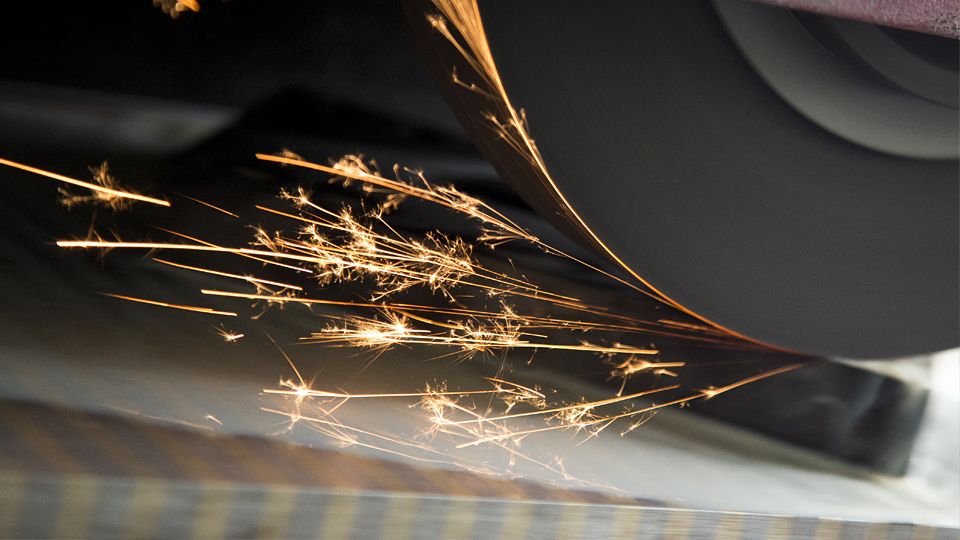

TIG welding

We weld with TIG method.

- It is welding with a non-consumable electrode in presence of inert shielding gases (argon, helium).

- In this method the electric arc forms between the welded material and the tungsten electrode.

- The method is used mostly to weld stainless steels, high alloy steels and aluminum.

Benefits:

- very high weld quality

- high purity of welds

- ability to weld very thin sheets

- no spatter of liquid metal

- capability to automate the procedure